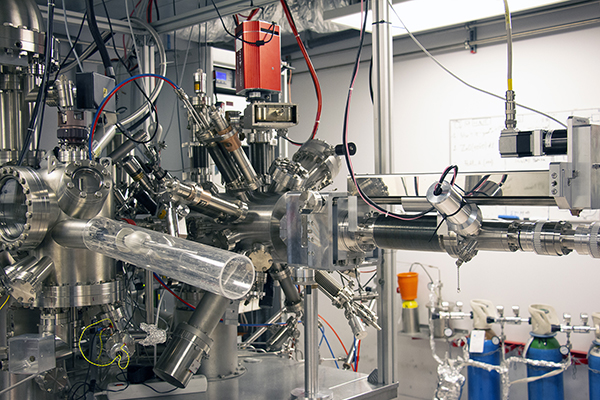

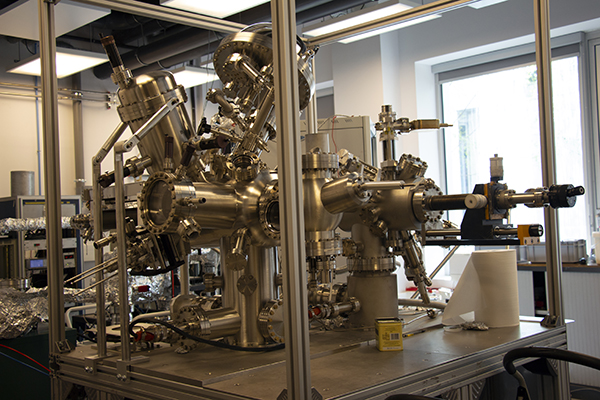

Two home-made vessels are dedicated to the analysis of surfaces and thin films of oxides in ultra-high vacuum environment. They allow for most of the surface science techniques and more specifically, they combine the local analysis by microscopy to the chemical analysis by electron spectroscopy. Of similar design, they are both divided into two chambers.

The analysis one includes:

- a near-field microscope of ScientaOmicron type, among which one at variable temperature under MATRIX electronics and one at room temperature under SCALA electronics. They allow imaging and studying the electronic properties of surfaces down to atomic scale either in current mode (STM, topography and spectroscopy) or in atomic force mode (AFM contact and non-contact);

- a photoemission analyser (EA125 5 channeltrons from ScientaOmicron or PHOIBOS 110 from SPECS with a 1D delay line detector) for the chemical analysis of surfaces by XPS and for the study of the valence band by UPS; the analyser is mounted on a µ-metal shielded chamber; the package I4P under IgorPro has been developed for the quantitative analysis of XPS spectra;

- a non-monochromated Al/Mg-Kα and/or Al-Kα monochromated (XR1000 fromScientaOmicron) X-ray sources;

- a UV source (HIS13 from Focus Gmbh) and/or a focussed ion gun for the surface analysis by Low Energy Ion Scattering;

- a multi-axis manipulator (from UHV-Design) compatible with Omicron sample plates, it can be cooled down by liquid nitrogen or helium and resistively heated up to 1200K.

© INSP – Cécile Duflot

The preparation chamber includes:

- a quadrupolar mass spectrometer (QMS200 from Pfeiffer) in thermal desorption configuration (TPD);

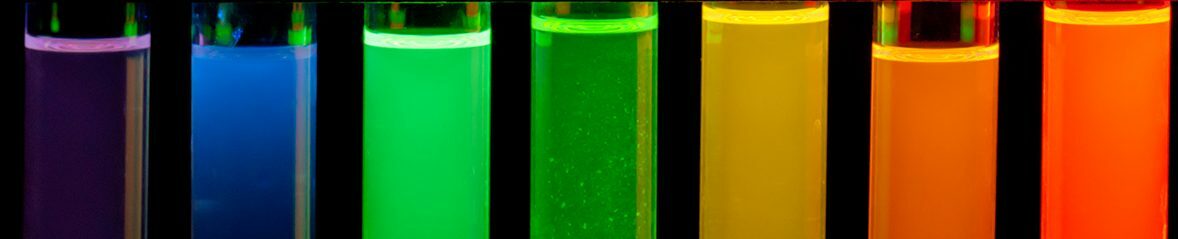

- silica viewports for real-time measurements by UV-visible differential reflectivity (SDRS, 200-1100nm) during evaporation or exposure to gases; a software GranFilm has been developed for dielectric calculations of Fresnel coefficients for layers of nanoparticles;

- several crucible or electron bombardment evaporators and a thermal cracker to produced atomic O/H for the growth of oxide films;

- a quartz microbalance;

- a multi-axis manipulator with a PID thermal control from liquid nitrogen temperature up to 1200 K;

- a home-made furnace based on electron bombardment to reach very high temperatures (>2000 K);

- an ion gun for the preparation of surface by bombardment;

- a gas introduction system with specific dosers;

- a load-lock system and a high-pressure chamber for exposure/annealing at pressures above the Knudsen regime.

© INSP – Cécile Duflot

The two vessels are equipped with ad hoc pumping and bake-out systems as well pressure gauges. All transfers are compatible with Omicron sample plates.

Contact

- Grégory Cabailh: cabailh(at)insp.jussieu.fr

- Stéphane Chenot: stephane.chenot(at)insp.jussieu.fr

- Stéphane Guilet: stephane.guilet(at)insp.jussieu.fr

- Rémi Lazzari: remi.lazzari(at)insp.jussieu.fr