List of members |

Facilities |

Internships and jobs |

PhD |

Publications |

News |

Team

- Permanent member: Tristan Baumberger

Extrusion is an industrial shaping process by which a fluid is pushed through a hole or a capillary. A wealth of instabilities are observed, either at the inlet, the outlet or the body of the pipe, which affet the surface of the core of the extruded fibre.

We focus on poorly explored issues:

- The role or the rheological properties (mainly shear thinning) on the existence and the very nature of the instabilities;

- The use of the extrusion flow properties and instabilities to process biomimetic fibers (artificial tendons or mussel byssus);

- The gelation kinetics of polymer solutions (alginate) via binding ion diffusion from the extrusion bath, taking advantage of the well define cylinfrical geometry of the extrudate.

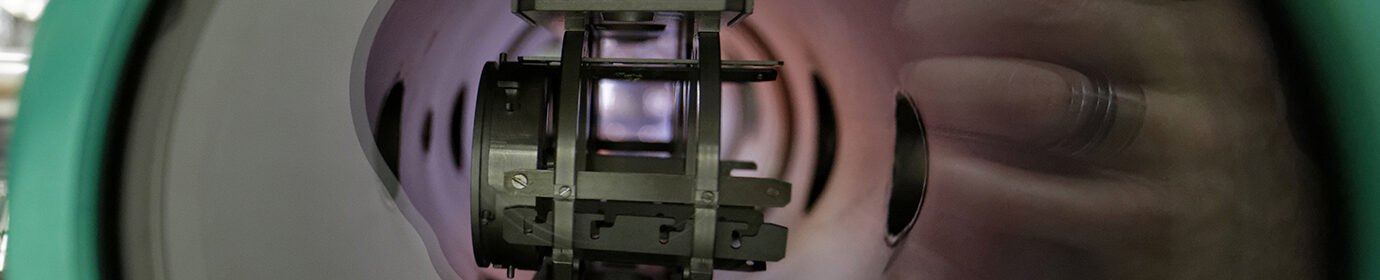

Caption: Extrusion of an alginate solution through a capillary with an internal diameter of 300 µm for increasing flow rates (from left to right) Beyond a criticalvalue of the flow rate, the extrudate adopts a helical profile revealing velocity oscillations in the capillary.

Publication

L. Picaut, O. Ronsin, C. Caroli, and T. Baumberger (2017) Experimental evidence of a helical, supercritical instability in pipe flow of shear thinning fluids, Phys. Rev. Fluids 2, 083303.

Fibre processing: Biomimicking Physical Mechanisms

Smart natural fibres

Fibres are ubiquitous in Nature (Spider Silk, Mussel Byssus, Tendons…).

Their aptitude to fulfil smart structural functionalities in changing and/or hostile environments is remarkable.

Multiple scale organisation, such as crimp of fibrils in tendons or cladding of byssus fibres is often a key to their outstanding performances.

A Physicist approach

At Institut des nanosciences de Paris we study instabilities which develop during micro-fluidic extrusion, self-assembling, or fracture of bio-polymeric systems (solutions and gels of alginate, gelatin…).

Some of them are able to mimick some structural features natural fibres (helical crimp, core-shell organization, inhomogeneities…).

Our aim is to understand and control these mechanical and physico-chemical instabilities and to assess their role in the ultimate mechanical properties of the processed fibres.

Caption: Extruded collagen fibre in the helical instability regime (scale bar = 300 µm). Left : bright field, the thread is extruded from top to bottom. Right : between cross polarizers (Lise Picaut, thesis).

Main collaborations

- Gervaise Mosser : Laboratoire de Chimie de la Matière condensée (Jussieu)

- Delphine Duprez : Laboratoire de biologie du développement (Jussieu

Recent publications

- L. Picaut, O. Ronsin, C. Caroli, T. Baumberger. Experimental evidence of a helical, supercritical instability in pipe flow of shear thinning fluids. Physical Review Fluids, American Physical Society, 2017, 2 (8), pp.083303. https://hal.sorbonne-universite.fr/hal-01614727

- L. Picaut, L. Trichet, O.Ronsin, B. Haye, I. Génois, et al.. Pure dense collagen threads from extrusion to fibrillogenesis stability. Biomedical Physics & Engineering Express, IOP Publishing, 2018, 4 (3), pp.035008. https://hal.sorbonne-universite.fr/hal-01850246

- L. Picaut, L. Trichet, C. Hélary, G. Ducourthial, M.-A. Bonnin, et al.. Core–Shell Pure Collagen Threads Extruded from Highly Concentrated Solutions Promote Colonization and Differentiation of C3H10T1/2 Cells. ACS Biomaterials Science and Engineering, ACS, 2021. https://hal.archives-ouvertes.fr/hal-03113880

- M.-J. Guerquin, B. Charvet, G. Nourissat, E. Havis, O. Ronsin, M.-A. Bonnin, M. Ruggiu, I. Olivera-Martinez, N. Robert, Y. Lu, K. E. Kadler, T. Baumberger, L. Doursounian, F. Berenbaum, & D. Duprez.Transcription factor EGR1 directs tendon differentiation and promotes tendon repair. The Journal of Clinical Investigation 2013 Vol. 123 Issue 8 Pages 3564-3576. https://www.jci.org/articles/view/67521