Nanopowders, agglomerates of ultrafine nanoparticles or nanoclusters, are of great scientific interest because they are a bridge between bulk materials and atomic or molecular structures. Various preparation techniques such as metal combustion, chemical synthesis in the vapour phase or the sol-gel process are used in our laboratory to manufacture samples of nanopowders with relatively uniform properties. Their characterisation is carried out via spectroscopic studies which aim to identify surface sites according to their electronic and geometric structure. This helps to elucidate their role in various processes ranging from the heterogeneous chemistry of surfaces to optical and electronic applications.

In our group, there are three main directions regarding studies on nanopowders:

- Pure metal oxides (e.g. MgO, ZnO): to obtain nanopowders with a high specific surface and control the abundance and nature of sub-coordinated reactive sites (steps, corners) through the synthesis operating conditions.

- Mixed metal oxides (ex: MgxZn1-xO): to obtain nanomaterials with new optical, catalytic, antibacterial properties.

- Supported noble metal nanoparticles (Ag/MgO, Au/MgO): to study epitaxial relationships and equilibrium forms of nanoparticles on complex surfaces.

Figure: Panel of nanopowder morphologies synthesised in the laboratory.

Characterisation usually includes a combination of the following three techniques:

- FTIR spectroscopy in transmission mode for the analysis of surface sites using probe molecules (H2, CO, H2O) in a pressure range from 10-7 to 103 Pa.

- Photoluminescence spectroscopy, the processes induced by light occurring at surface sites.

- Transmission electron microscopy (TEM) for morphology.

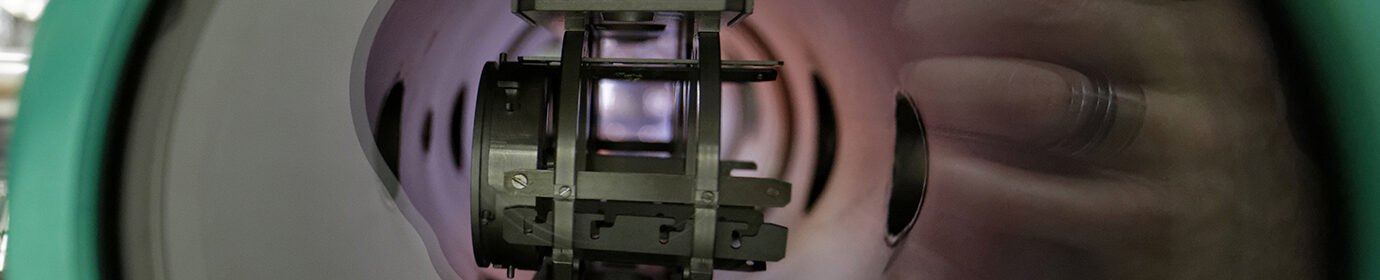

Caption: “Homemade” glove box for the synthesis of nanopowders by combustion in a controlled atmosphere. © INSP

Contact

- Stéphane Chenot : stephane.chenot(at)insp.jussieu.fr

- Slavica Stankic : slavica.stankic(at)insp.jussieu.fr