How irregular composite growth patterns become regular: a coupling dynamics

The morphological transition from disordered or irregular solidification microstructures to regular shapes in partially faceted eutectic alloys is an important phenomenon in the metallurgy of industrial alloys (e.g., aluminum-based). For a better understanding of the underlying physical mechanisms, in situ solidification experiments with real-time monitoring of two-phase growth patterns were conducted at INSP (optical microscopy) and at the University of Michigan (synchrotron X-ray nano-tomography, Brookhaven National Laboratory), taking the Al-Al3Ni eutectic as a model system. The result evidences a qualitative evolution, by increasing the solidification rate, from an irregular, decoupled growth of faceted Al3Ni crystals towards a diffusion controlled coupled growth, more generally associated to nonfaceted eutectics, leading to the formation of regular, rod-like microstructures. This experimental study, which will be supplemented by a theoretical analysis based on numerical simulations, contributes to a profound renewal, in general terms, of our scientific approach to faceted composite growth, also opening the way to better control of microstructures in a wide range of materials.

The morphological transition from disordered or irregular solidification microstructures to regular shapes in partially faceted eutectic alloys is an important phenomenon in the metallurgy of industrial alloys (e.g., aluminum-based). For a better understanding of the underlying physical mechanisms, in situ solidification experiments with real-time monitoring of two-phase growth patterns were conducted at INSP (optical microscopy) and at the University of Michigan (synchrotron X-ray nano-tomography, Brookhaven National Laboratory), taking the Al-Al3Ni eutectic as a model system. The result evidences a qualitative evolution, by increasing the solidification rate, from an irregular, decoupled growth of faceted Al3Ni crystals towards a diffusion controlled coupled growth, more generally associated to nonfaceted eutectics, leading to the formation of regular, rod-like microstructures. This experimental study, which will be supplemented by a theoretical analysis based on numerical simulations, contributes to a profound renewal, in general terms, of our scientific approach to faceted composite growth, also opening the way to better control of microstructures in a wide range of materials.

Reference

From irregular to regular eutectic growth in the Al-Al3Ni system: In situ observations during directional solidification

Paul Chao, Shanmukha Kiran Aramanda, Xianghui Xiao, Sabine Bottin-Rousseau, Silvère Akamatsu, Ashwin J. Shahani

Acta Materialia, Volume 280, 2024,120314

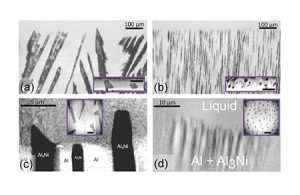

Figure: Real-time images of composite, eutectic growth patterns at the solid-liquid interface during directional solidification of thin (10 to 50 µm thick) Al-Al3Ni samples. The solid grows from bottom to top at a controlled rate V in the vertical direction. The Al3Ni crystals appear dark-grey; there is a poor contrast between the liquid and the solid aluminium. (a) and (b): in situ optical microscopy (reflected light). Insets: ex situ images (SEM) of cross-sections (FIB) of the metallic film. (c) and (d): in situ synchrotron X-ray nano-radiography (insets: ex situ cross-sections by X-ray nano-tomography). Bars in insets: 10 µm. The images illustrate the morphological transition from irregular (decoupled) growth patterns at low solidification rate (V = 0.5 µm/s) in (a) and (c), to (quasi) regular (coupled) growth patterns at higher V values (5—10 µm/s) in (b) and (d).