Band and hexagon patterns: the lamella-to-rod transition during composite eutectic growth

Contact : akamatsu@insp.jussieu.fr ; 01 44 27 63 99 ; bottin@insp.jussieu.fr; 01 44 27 61 20

Funding : CNRS - Sorbonne Université

keywords : Internship M2

Gratification : Oui

Team(s) internship page(s) : Chemical Physics and Dynamics of Surfaces

Internship description

Click on description for full document

Keywords: solidification, in situ experiments, microgravity, numerical simulations

Scientific description:

Microgravity studies are the key to unique advancements toward a better understanding of the formation of solidification microstructures in alloys. In situ experiments with real-time optical imaging of the growth front patterns are performed onboard the International Space Station (ISS) in purely diffusion controlled conditions. They can be compared to the available theory, mostly via numerical simulations. We propose to study complex phenomena observed during directional solidification of a model transparent eutectic. A eutectic mixture solidifies directly into a composite material with two-phase, basically lamellar or rod-like, microstructures. They are delivered by micrometric coupled-growth patterns at the moving solid-liquid interface, which present regular arrangements –bands or hexagons– of the two solids in a planar geometry. A key issue, for industrial applications, is to control the shape and the size of the microstructures. This requires a deeper knowledge of morphological

instabilities, in particular the so-called lamellar-to-rod transition. Recent solidification experiments in microgravity bring new experimental evidence. However, for an accurate analysis, several blocking points must be overcome. The student at INSP will be involved in

1- quantitative measurements using images obtained during previous microgravity campaigns (this presents challenging aspects as regards image processing and analysis), and

2- onground solidification experiments in the laboratory, using different alloys. Depending on the advancement of the study, numerical simulations (phase field) can be carried out (coll. Mathis Plapp; Ec. Polytechnique). Expected outcomes include a better identification of the relevant physical parameters and the underlying morphological-instability modes.

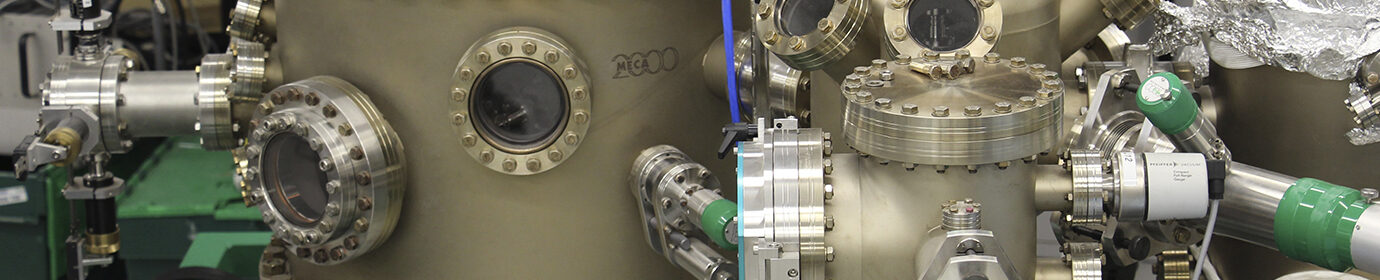

Techniques/methods in use: solidification setup, optical microscopy, image analysis, (possibly: numerical simulations)

Applicant skills: materials science and/or nonlinear physics

Industrial partnership: Y (CNES/ESA)

Possibility for a Doctoral thesis: Y