Salle 317

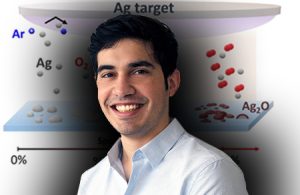

Ramiro Zapata, doctorant dans l’équipe Oxydes en basses dimensions

Ramiro Zapata, doctorant dans l’équipe Oxydes en basses dimensions

Study of the effect of gaseous additives on the growth of Ag films during magnetron sputtering deposition, using in situ and real-time measurements

Complex dielectric thin-film stacks containing Ag layers (with a thickness of roughly 12 nm) are deposited on glass surfaces to produce “Low-E” glazing products, for enhanced thermal insulation applications. Magnetron sputtering deposition is the industrially relevant technique used for their production. Current research efforts in the area aim at finding ways of controlling the out-of- equilibrium growth of the metal film and its resulting microstructural properties, with the purpose of improving the insulation efficiency of the glazing whilst maintaining a low metal thickness and high

optical transmission in the visible region.

In this context, the use of so-called “surfactant” gas additives during sputtering deposition has garnered much attention over the last years. These gases act upon the growing Ag film to counterbalance the 3D Volmer-Weber growth mode and force a more 2D-like growth. Ideally, they should allow for the deposition of thinner, conductive films without compromising their conductivity and without incorporating into the film. However, beyond the ideal picture, the exact role of these additives and the mechanisms involved remain unclear.

The effect of two “surfactant gases”, namely N2 and O2, on the growth of Ag films during magnetron sputtering deposition was studied using a combination of real-time measurements (performed during film deposition) and in situ measurements (performed after deposition, with no contact with the atmosphere during sample transfer). Real-time electrical film resistance was used to probe the percolation threshold thickness and film resistivity, while Surface Differential Reflectance Spectroscopy provided information on the wetting behaviour of the Ag nanoparticles in the initial growth stages. Film chemistry was characterized using in situ X-Ray Photoelectron Spectroscopy. These analyses were further supplemented by ex situ Transmission Electron Microscopy and X-Ray Diffraction measurements.

A systematic study was performed as a function of the fraction of O2 or N2 in the gas flow going into the deposition chamber. Both gases were shown to promote the formation of a conductive and continuous film at a lower deposited thickness than for deposition under pure Ar, mostly by acting upon the initial steps of film growth (nucleation, growth and coalescence) and by affecting the texture and crystallinity of the Ag film. A complex Ag oxidation chemistry was observed in the case of O2, but no nitride formation could be evidenced for N2 addition. By modifying the Ag metal surface energy, the addition of surfactant gases leads to increased nanoparticle wetting in the initial growth stages, but

also leads to competition between different crystallographic orientations. This effect, alongside film oxidation in the case of O2, results in a delayed coalescence between nanoparticles, and a decrease in film conductivity.

Finally, to see how the impact of these gases differs depending on the substrate, Ag deposition on SiO2 and on aluminium-doped zinc oxide (AZO) underlayers was compared. The lower energy of the metal- substrate interface as well as the improved (111) texturation of the Ag films on AZO led to improved nanoparticle wetting and the formation of continuous, more conductive films at a lower thickness. The film oxidation dynamics were also shown to depend on the substrate, with composition profiles for the Ag films showing a higher oxide fraction near the metal-substrate interface for AZO underlayers.

Jury

Mme. Christine ROBERT-GOUMET (Université Clermont-Auvergne)

- Grégory ABADIAS (Université de Poitiers)

- Pascal ANDREAZZA (Université d’Orléans)

- Abhay SHUKLA (Sorbonne Université)

- Hervé MONTIGAUD (Saint-Gobain Recherche Paris)

- Rémi LAZZARI (Sorbonne Université)